Blenders

- Home

- Blenders

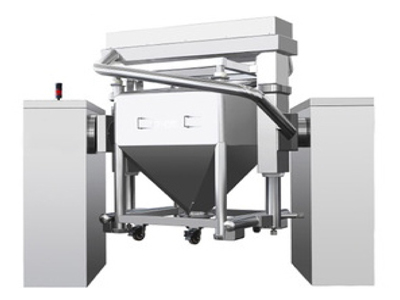

CONTA [5 L to 1000 L]

V TYPE [5 L to 1000 L]

- Consists of two large diameter pipes cut to 80ºangle and welded together to form a V Shaped body. Inlets are located on top of the body, outlet is at the bottom of V point where there is transition from an elliptical to cylindrical discharge port.

- Easy to clean

- Minimum Maintenance

- The Bin charging system can also be incorporated in it which is a dust free closed system for charging and discharging of powders or granules

- Dry powder to powder mixing for tablets and capsules formulations

- Dry granules sub lots mixing to increase the batch size at bulk lubrication stage of tablet granules

- Dry powder to wet mixing

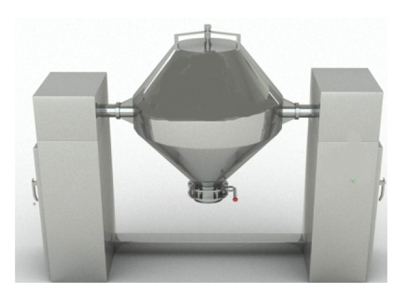

Double Cone [5 L to 1000 L]

- The Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously.

- The conical shape at both ends enables uniform mixing and easy discharge.

- The cone is statically balanced to avoid any excessive load on the gear box and motor

- While the power can be loaded into the cone through a wider opening, it can be discharged through a butterfly or slide valve

- Depending upon the characteristic of the product, paddle type baffles can be provided on the shaft for better mixing

- The contact parts are made of S.S.316

- Flame proof electrical can be provided as optional

- Capacity available 5 L to 1000 L

- The working capacity can be exchanged to 70 % of gross capacity by validated study

OCTAGON BLENDER [5 L to 1000 L]

- Octagonal Blender, due to its octagonal shape is designed to process larger volume of material. It occupies less space compared to other similar blenders like ‘V’ and Double Cone.

- Power consumption is also less. The blending takes place at low speed during operation. It is well balanced even in higher capacities. It is very useful for pharmaceutical industries wherein gentle blending of dry granules of powder is to be done. It is a slow speed blender and has removable type baffles mounted on a rectangular shell. The important

- Feature of the machine is easy to wash in place. Octagonal blender is supplied with a bin charging system or can be designed for vacuum charging. Dust free charging system is also incorporated, which is a completely closed system for charging and discharging of powders or granules.