Conveyer System Pneumatic

- Home

- Conveyer System Pneumatic

CONVEYER SYSTEM-PNEUMATIC (Range 300kg/hr To 4000kg/hr )

- Two major types of powder conveying systems: Mechanical and pneumatic conveyors.

- Selecting Pneumatic Conveying Systems

- Pneumatic conveying systems are a popular choice for many powder processors, largely due to the fact that they customize to the unique requirements of a specific plant or materials being processed.

- A pneumatic conveying system moves dry bulk powders through horizontal or vertical pipelines by using an air stream. Traditionally, pneumatic conveying systems include an air source, an infeed device, a conveying line, a receiver and dust filtration.

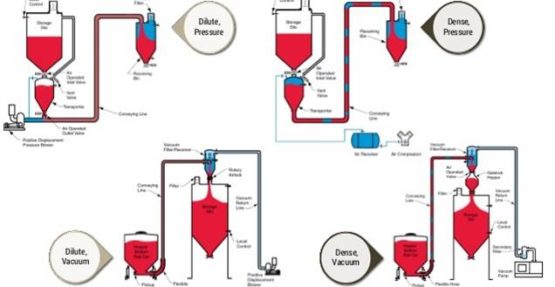

- Types of Pneumatic Conveying Systems

- Pressure Dilute Phase

- are one of the most common and practical pneumatic conveying types for powder processing. They are often used when conveying powders where abrasiveness, degradation and segregation are not a concern.

- Vacuum Dilute Phase

- are used in similar applications to pressure dilute phase conveying, such as continuous conveying and not requiring degradation and segregation to be a priority. Where it differs is that a filter receiver rated for vacuum is required. Typically, this system conveys materials at lower capacities and over a shorter distance.

- Pressure Dense Phase

- are a great system to use if the material you’re moving is fragile or abrasive over longer distances. These systems feature a gas boosters that points along the convey line to maintain the control of velocity. With this type of system, powder can remain in the conveying line while the vessel is refilled with powder.

- Vacuum Dense Phase

- are also used to transport fragile or abrasive materials. As opposed to pressure dense phase system, vacuum dense phase systems are used to convey fragile materials over short distances.

VACUUM DENSE PHASE

| Model | PVD3 | PVD10 | PVD20 | PVD30 | PVD50 | PVD100 |

| KG/HR | 300 | 900 | 1200 | 2000 | 3000 | 4000 |

| HEIGHT | 600 mm | 1000 mm | 1100 mm | 1400 mm | 1600 mm | 1700 mm |

| DIA | 270 mm | 450 mm | 450 mm | 450 mm | 450 mm | 450 mm |

| VOLUME | 3 LTR | 10 LTR | 20 LTR | 30 LTR | 50 LTR | 100 LTR |